CONSULTANT Services

Loss eradication done right.

Design for X is a consulting firm that develops our clients’ core competency in systematic loss eradication through all aspects of the value chain. Our approach combines proprietary cross-industry experience, AI-driven optimization, and hands-on training to design, implement, and sustain lean systems that drive operational and cultural excellence.

We incorporate the original intent of Seiichi Nakajima, the creator of TPM principles, in the design, execution, and control of our operational-excellence systems. We benefit from a master-apprentice transmission of knowledge that can be traced directly to Nakajima and our own generation of knowledge from project-defect analysis across the globe. We don’t offer clients a “flavor-of-the-month” program or non-value-added spreadsheets far removed from their original intent. We offer the cultural change management (human and method) required to understand the intent, develop, and execute the tools required for world-class manufacturing.

Design for Excellence (DfX)

Align product and equipment design efforts with downstream goals for lifecycle efficiency.

- Conduct stakeholder and current-state analysis to design and integrate DfX methodologies into new product development (Early Product Management) and/or CapEx (Early Equipment Management) processes.

- Develop custom checklists for Design for Manufacturability, Reliability, Operability, Quality, Cost, Maintainability, Safety, Supply Chain, Regulatory Compliance, and other priorities to ensure loss eradication.

- Provide training in routine management techniques, including stage-gate processes, design reviews, project defect analysis, and feedback loops, to sustain DfX and build a corporate knowledge repository.

Operational Excellence

Transform operations with lean methodologies and cultural alignment for sustained performance.

- Design and implement lean operational structure based on World Class Manufacturing (WCM) or Total Productive Maintenance (TPM) pillars (e.g., Focused Improvement, Autonomous Maintenance, Quality, Training & Education, Early Management).

- Design and implement customized hybrid Operational Excellence approaches, integrating TPM principles and best-in-class tools into existing organizational structures without program rebranding or redundancies.

- Deliver immersive training in continuous-improvement tools (e.g., DfX, 5S, FMEA, SMED, DMAIC, RCM) through workshops like autonomous maintenance to restore equipment to baseline condition and implement a sustainment process from the learnings.

- Optimize organizational structures for Continuous Improvement, Project Engineering, and CapEx management with process flows, procedural tools, AI-enhancement, training, and skill validation.

Greenfield and Brownfield (Vertical Startup)

Ensure seamless project execution for new and existing facilities with loss-prevention strategies.

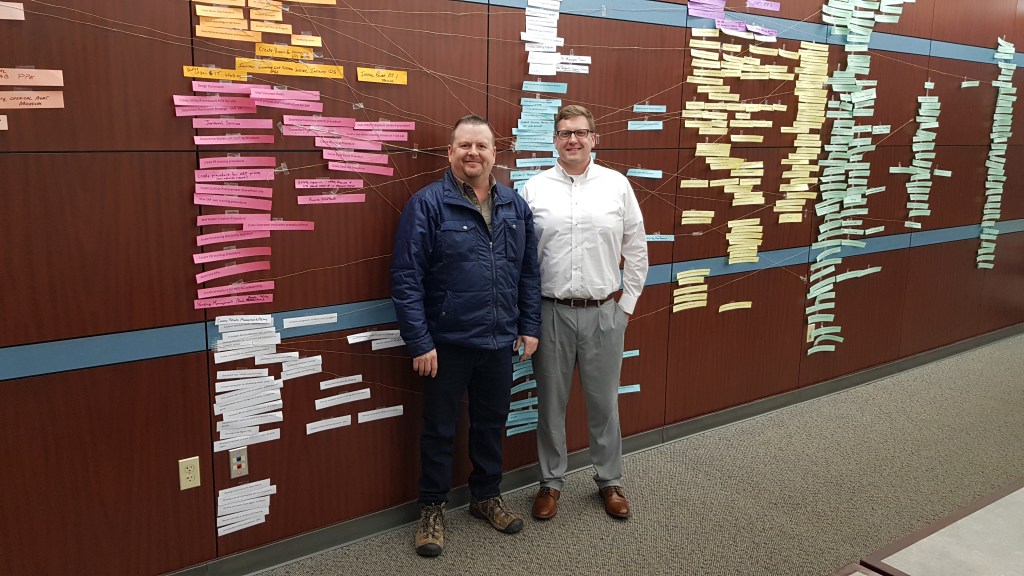

- Facilitate onsite affinity diagramming to develop Work Breakdown Structures (WBS) for construction and operational readiness plans.

- Provide customized project management training, including plan development, Gantt chart visualization, phase-gate processes, DfX checklists, and critical-path analysis.

- Provide end-to-end support for workforce recruitment, customized operator and technician training programs (including hands-on learning and safety protocols), supplier and vendor coordination for timely material and equipment delivery, supply chain setup with inventory management systems to ensure production readiness and scalability, and Reliability Centered Maintenance (RCM) within a CMMS-managed corrective and preventive work process.

- Conduct rigorous equipment Factory Acceptance Tests (FAT), Site Acceptance Tests (SAT), and pilot runs, alongside regulatory compliance audits (e.g., OSHA, environmental permits) and process validation to guarantee quality, safety, and operational stability before and during startup.

- Implement Project Defect Analysis methodology to mitigate risks like late completion or scope creep, using process tools and AI to identify and mitigate causation variables.

- Conduct CapEx project post-mortem workshops with machine learning to create a continuous-improvement feedback loop, replacing tribal knowledge with a central corporate repository of knowledge.

Process Optimization

Streamline operations with data-driven solutions for supply chains, agencies, and business units.

- Optimize processes using lean methods and AI to analyze historical data and predict inefficiencies in supply chains, organizational hierarchies, or governmental procedures.

- Lead targeted kaizen events, from charter creation to control implementation, with proprietary stakeholder review checklists.

- Train teams in continuous-improvement techniques and develop customized procedural frameworks and training for any system or process.

Reliability Centered Maintenance (RCM)

Maximize asset performance with cost-effective, AI-prioritized maintenance strategies.

- Design, training, and implementation of RCM programs to identify and execute the most cost-effective, asset-management strategies with AI-based probability assessments and prioritization.

- Provide CMMS design, development, and training for asset management in SAP and other software solutions including preventative maintenance plan strategies, equipment management, work order management, failure-code trees, and methodologies for work order cost allocation/reporting, MTBF/MTTR reporting, and functional location hierarchy.

- Provide Nondestructive Testing (NDT) training and condition-based monitoring program development to decrease monetary losses in the manufacturing process and improve environmental sustainability including hands-on instruction for the use of ultrasonic detection equipment to identify and eliminate compressed air leaks and other utility system losses.

Simulation Modeling

Unlock operational insights with advanced simulations for bottleneck analysis and KPI forecasting.

- Provide Monte Carlo simulation modeling design, analysis, and reporting for manufacturing processes to identify bottlenecks, critical equipment needs (in-line spare, spare part inventory requirements), forecasted KPI data, optimal production run sequencing, and other optimization opportunities.

- Use our commercial license for AnyLogic industry-leading simulation software to provide clients with executable JAVA versions of their simulation without the need for additional software or licenses.

- Provide actionable recommendations from simulation analyses to enhance throughput and resource efficiency.

TEAM MEMBER PROFILE

The right talent to design the right solution

“It’s common to enter a plant and see ‘pockets of excellence’ in place of uniform excellence. There’s often a semblance of continuous-improvement foundational concepts like jishu hozen, kobetsu kaizen, and hinshitsu hozen, but the intent and subsequent organizational culture have been completely lost in translation. I’ll see more effort placed on programmatic spreadsheets than restoring and sustaining equipment in its baseline condition–a guaranteed death certificate for any corporate operational excellence program. True loss eradication requires the proper design of the methodologies and experiential learning techniques to produce the profound knowledge needed for execution.”

– Noah O’Brien, Technical Director